Federal grant supports development of new carbon-capture technology

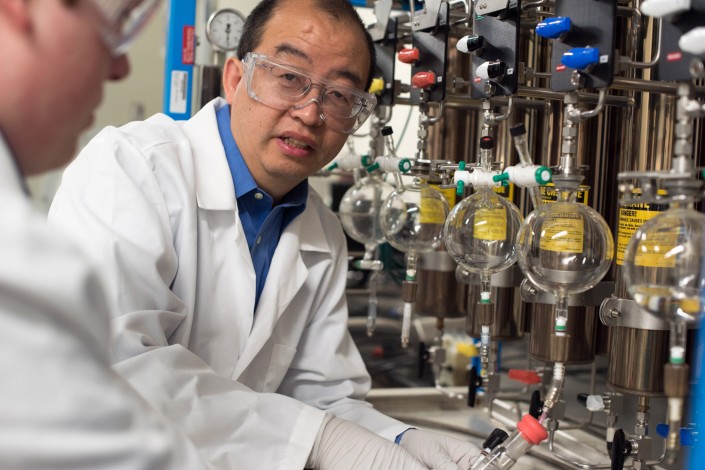

Image: The College of Science

In 2012, Texas A&M University chemist Hongcai Joe Zhou’s research resulted in a novel carbon-capture technique – in essence, a flypaper-like “trap” – poised to significantly reduce the amount of carbon dioxide (CO2) emitted by power plants across the nation and world.

Three years later, Zhou’s latest proposal on carbon-capture research is one of 16 selected nationwide by the United States Department of Energy (DOE) National Energy Technology Laboratory (NETL) to advance new CO2 storage technologies. The grants, announced earlier this month, are being awarded through the NETL’s Carbon Capture Program, which funds development and testing of transformational CO2 capture systems for new and existing coal-based power plants.

Research funded by this program is expected to help overcome limitations of singular, standard gas treatment systems, such as those based on solvents, sorbents or membranes alone.

Zhou will receive nearly $1.5 million from the DOE along with $361,000 in non-DOE funding for a total of $1.8 million in support of his proposal, “Evaluation of Amine-Incorporated Porous Polymer Networks as Sorbents for Post-Combustion CO2 Capture.”

In collaboration with Colorado-based Advanced Clean Energy Solutions, LLC, and College Station-headquartered framergy® Inc., Zhou will seek to develop highly porous materials with high CO2 affinity capable of capturing it from flue gases with low parasitic energy consumption.

Zhou, a professor in the Texas A&M Department of Chemistry since 2008 and holder of the Robert A. Welch Chair in Chemistry, is a world leader in the design of framework materials — precisely arranged and highly porous polymer-based structures that hold promise in a variety of energy and environment-related areas and applications. These framework materials include metal-organic frameworks (MOFs) and porous polymer networks (PPNs).

Zhou’s group currently holds the world record in surface area for a porous organic polymer.