Cut Qatar’s CO2 output? New tech for natural gas may provide answers

Qatar is one of the world’s top producers of natural gas — and unfortunately, the carbon dioxide that comes with processing the natural resource into usable products. But a novel process developed by Texas A&M University at Qatar researchers could help Qatar process its wealth of natural gas while reducing the country’s carbon footprint.

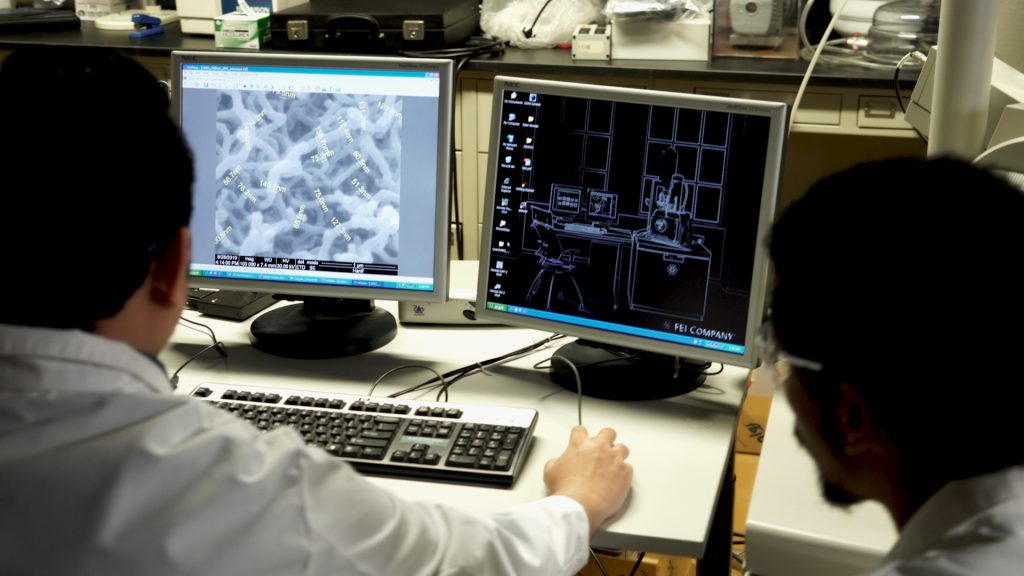

Developed in Qatar, the CARGEN reactor technology was conceived and designed by Professor Nimir O. Elbashir and his research team at Texas A&M’s Qatar campus in collaboration with Professor Mahmoud M. El-Halwagi and his co-worker Debalina Sengupta from the Artie McFerrin Department of Chemical Engineering at Texas A&M’s main campus in College Station. This technology is believed to be the first of its kind that processes natural gas (methane) and captured carbon dioxide (CO2) to produce both syngas, a valuable precursor to numerous hydrocarbon feedstocks that drive Qatar’s economy, and high-quality solid carbon nanotubes (CNTs). And unlike conventional processes, all without releasing more CO2 into the atmosphere.

Elbashir’s research focuses on converting natural gas into valuable hydrocarbon products, including ultraclean fuels or useful chemicals, in a process called gas-to-liquid conversion, or GTL. A major drawback of GTL processing is that it produces a lot of CO2, which increases Qatar’s carbon footprint and has led to the tiny country being named the world’s leading producer of CO2 per capita.

Under the umbrella of the Texas A&M Engineering Experiment Station (TEES) Gas and Fuels Research Center (GFRC) headquartered at the Qatar campus, Elbashir and researchers at both campuses have focused on how to reduce CO2 emissions and reduce Qatar’s carbon footprint. Elbashir directs the GFRC, one of the largest TEES research centers and a major initiative, bringing together 32 multidisciplinary scientists and professors from Texas A&M’s campuses in Texas and Qatar, all working in the same area but from different angles to speed up technology development in natural gas processing.

The CARGEN technology was developed to advance the dry reforming of natural gas, which is especially attractive as it converts methane and CO2 (both greenhouse gases) through a reactor to produce syngas, a mixture of carbon monoxide and hydrogen that is then processed to make liquid hydrocarbons and ultraclean fuels. This process, however, requires a lot of heat to drive the chemical reactions. This heat usually comes from burning fuels, which emits even more CO2.

Elbashir’s team has designed the novel CARGEN — or CARbon-GENerator — reactor, a second reactor added to the reforming process, along with a catalyst to drive the chemical reactions to produce expensive carbon nanotubes and syngas from CO2 and methane. These high-quality carbon nanotubes can be used in several industries in Qatar, including steel and cement, while the syngas can be turned into ultra-clean fuels and value-added products. The process can be driven by either electric or solar power, eliminating the need to burn fuel and thereby resulting in much lower CO2 emissions than conventional technologies.

“We are making Qatar CO2 emissions into two products that are important to the economy in Qatar and will broaden the role of hydrocarbons in Qatar’s manufacturing facilities,” Elbashir said. “CNTs are very expensive and extremely versatile, and can be used to manufacture products such as computers and other high-quality materials. And at the same time, we are also producing syngas, which can then be used to make the chemicals Qatar’s processing industries rely on.”