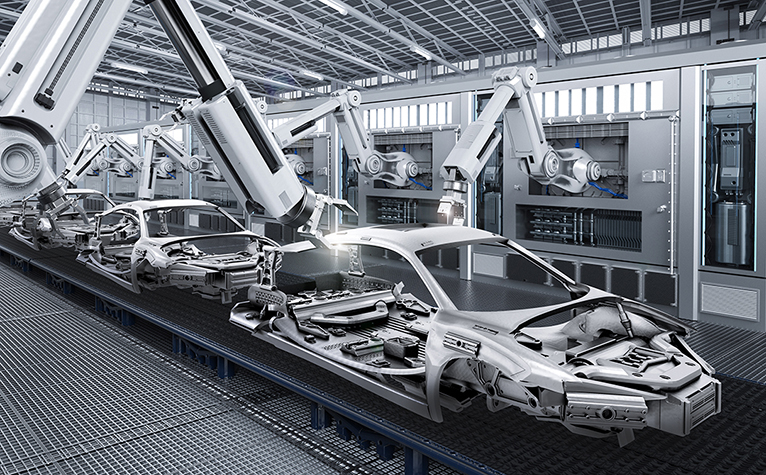

Replacing aluminum with magnesium may create lighter, stronger vehicles

Researchers from the Texas A&M University College of Engineering, the Texas A&M Engineering Experiment Station (TEES) and Los Alamos National Laboratory (LANL) are improving magnesium alloys’ usability, which could mean stronger, lighter vehicles with improved gas efficiency.

The researchers are working to improve magnesium alloy manufacturing processes to make the alloy easier to use for a variety of applications. The team includes Ibrahim Karaman, Amine Benzerga and Alan Needleman from the Department of Materials Science & Engineering, which is administered jointly by the colleges of engineering and science; doctoral student Wahaz Nasim from TEES; and Ricardo Lebensohn from LANL.

Currently, aluminum alloys are most commonly used in aerospace, defense and automotive components because they are light and easy to manipulate at room temperature. However, magnesium is more than 30 percent lighter than aluminum. If magnesium alloys could be fabricated and processed more easily and strengthened through processing, then using magnesium alloys in place of aluminum could significantly reduce fuel consumption and carbon footprints and enhance maneuverability in transportation due to the lighter weight and higher specific strength.

Unfortunately, magnesium is difficult to manipulate into different forms at room temperature and it is difficult to process the alloys. Current methods require high temperatures to manipulate magnesium, which raises costs and decreases the overall alloy strength.

Through thermomechanical processing methods, researchers at TEES have the ability to further strengthen magnesium alloys and the potential to increase formability of magnesium alloys at room temperature.

According to Karaman, LANL plays an important part in this project because they have one of the best modeling approaches for predicting the behavior of metals. The results of their modeling will inform how TEES researchers process the magnesium alloy in order to determine the appropriate methods for making it easier to work with.

The processing methods these researchers are exploring are based on the idea that one can engineer the anisotropy of magnesium alloys. Anisotropy refers to how substances display variations in physical properties along different material crystal directions and sample axes. A simple visual example would be wood. Wood is easier to split along the grain than across it.

As Benzerga explained, “It is time to engineer that which we cannot suppress. Materials scientists have been trying to suppress or minimize the anisotropy of wrought products, especially in technologically important lightweight applications, such as aluminum alloys and magnesium alloys. Our goal is not to suppress anisotropy but to engineer it so as to actually improve material performance.”

This collaboration is made possible by the Texas A&M System National Laboratories Office and LANL.