Tattoo tech: Electricity can zip through this new 3D ink like it’s skin; up next … bioelectronic implants

A team of researchers at Texas A&M University has developed a new class of biomaterial inks that mimic native characteristics of highly conductive human tissue, much like skin, which are essential for 3D printing.

This biomaterial ink leverages a new class of 2D nanomaterials known as molybdenum disulfide (MoS2). The thin-layered structure of MoS2 contains defect centers to make it chemically active and, combined with modified gelatin to obtain a flexible hydrogel, comparable to the structure of Jell-O.

“The impact of this work is far-reaching in 3D printing,” said Akhilesh Gaharwar, associate professor in the Department of Biomedical Engineering and Presidential Impact Fellow. “This newly designed hydrogel ink is highly biocompatible and electrically conductive, paving the way for the next generation of wearable and implantable bioelectronics.”

Flexible electronics have enabled the design of sensors, actuators, microfluidics and electronics on flexible, conformal and/or stretchable sublayers for wearable, implantable or ingestible applications. However, these devices have very different mechanical and biological properties when compared to human tissue and thus cannot be integrated with the human body.

The ink has shear-thinning properties that decrease in viscosity as force increases, so it is solid inside the tube but flows more like a liquid when squeezed, like ketchup or toothpaste. The team incorporated these electrically conductive nanomaterials within a modified gelatin to make a hydrogel ink with characteristics that are essential for designing ink conducive to 3D printing.

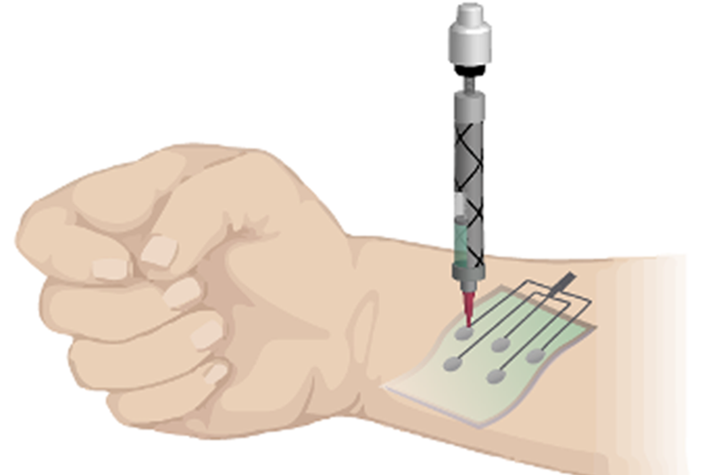

One of the potential applications of the new ink is in 3D printing electronic tattoos for patients with Parkinson’s disease. Researchers envision that this printed e-tattoo can monitor a patient’s movement, including tremors.