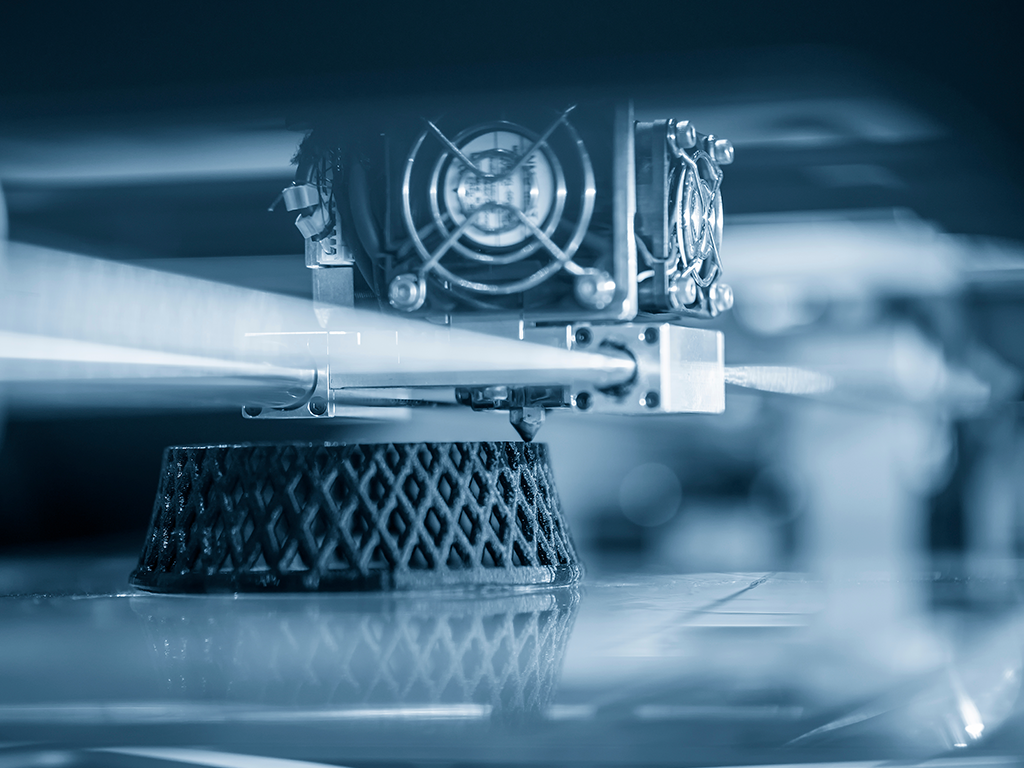

A&M engineers looking for ways to enhance titanium components through 3D printing

Pixel B/shutterstock.com

The Digital Manufacturing and Distribution lab (DMD-Lab) at the Texas A&M Engineering Experiment Station (TEES) and the Virtual Foundry have partnered to explore the effects of varying sintering parameters on FFF 3D printed titanium alloy parts. Fused Filament Fabrication (FFF) is an additive manufacturing technology in which an object is manufactured by adding and fusing melted material one layer at a time to create 3D objects.

The Virtual Foundry offers metal 3D printing technology that can be sintered in-house and does not require cloud-based software.

This collaboration has the potential to impact healthcare, aerospace and many more industries. According to Dr. Chukwuzubelu Ufodike, director and assistant professor, DMD-Lab and Department of Engineering Technology and Industrial Distribution at Texas A&M University, the anticipated product is supposed to be high-strength titanium components with improved mechanical properties, dimensional accuracy and surface quality.

The goal of this collaboration is to advance the understanding of the relationship between sintering parameters and the properties of FFF 3D-printed titanium alloy parts.

“Through our collaborative research at the DMD-Lab, we aim to uncover critical insights into microstructural evolution and mechanical behavior resulting from variations in sintering parameters,” said Ufodike. “Our joint efforts will enhance our knowledge of how these parameters influence dimensional accuracy and surface quality, opening up new avenues for material development and additive manufacturing processes.”

“The synergy between this exceptional research environment and The Virtual Foundry’s expertise ensures that our collaboration is poised to make a lasting impact on the field of additive manufacturing,” Ufodike said.